Laser marking: How to increase the marking rate of fiber las_Huacai Transfer printing

The laser marking machine uses a laser to permanently mark the surface of a variety of materials. The actual effect of the marking machine is to reveal deep-seated substances according to the volatilization of surface substances, and then to carve exquisite pattern designs, trademark logos and texts. The laser marking machine is divided into CO2 laser marking machine, semiconductor material laser marking machine, fiber laser marking machine and YAG laser marking machine.

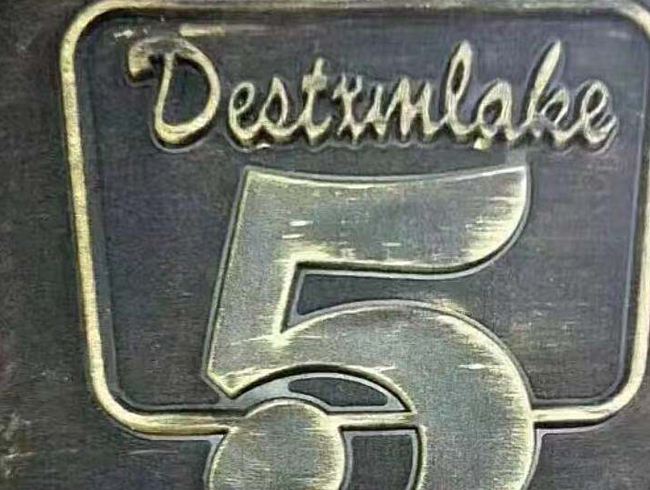

The laser marking machine can manually engrave a variety of non-metallic materials. Used in clothing accessories, medical equipment, white wine packaging boxes, ceramics, beverages, textile laser cutting, rubber and plastic products, cabinet factory nameplates, craft products, electronic components, leather products and other fields.

When purchasing a fiber laser marking machine, everyone pays great attention to the marking rate of the machine and equipment, because this is immediately related to the production volume of the order information. So, what aspects will harm the marking rate of the fiber laser marking machine?

The fundamental reason why fiber laser marking machine harms the marking rate of fiber laser marking machine:

There are two common reasons that harm the marking rate of fiber laser marking machines. One is internal factors, mainly the machinery and equipment itself, and the other is the production and processing of product workpieces.

Reason 1: The machine equipment itself is mainly due to the laser frequency, laser spot mode and light emission angle, laser output power, effective electron optical plastic cosmetic production and processing auxiliary vapor and material. Customers should take this into consideration when purchasing a fiber laser marking machine, and make selections based on the proposal of a technical professional and technical engineer.

Reason 2: The key includes the size of the laser spot, the marking strength, the relative density of the marking, and the depth of the marking. Laser spot size: the smaller the spot, the smaller the matching marking volume. Therefore, the larger the light spot, the faster the marking rate.

Marking width: Because the total offset area of the scanning galvanometer for large-format marking is enlarged, the marking speed of large-format marking is slower than that of small-format marking.

Relative Marking Density: Under the same intensity, same light spot, and same deep level, the higher the relative density of marking, the slower the corresponding marking speed, because the relative density immediately increases the total marking area.

Marking deep layer: According to necessity, if it is necessary to increase the deep layer marking, the main parameters of the fiber laser marking machine must be adjusted to increase the output power, current and other factors of the fiber laser marking machine, thereby jeopardizing the marking speed.

The above is the fundamental reason that endangers the marking speed of fiber laser marking machine. Laser marking is to use laser to carry out permanent marking on the surface of various materials. The actual effect of marking is based on the volatilization of surface substances to expose deep-seated substances, or according to the organic chemical state changes of surface substances caused by solar energy to "carve" imprints, or according to the solar energy to burn some substances, indicating that ion implantation is necessary. And text.

推荐产品Recommended Products

Related transfer recommendations

- What is flocking printing?

- What is flocking paper? What are the advantages and disadvan

- What is the washing water mark?

- What is flockde paper

- The advantages and disadvantages of flocking wallpaper Const

- How to do flocking

- How to use heat transfer flocking heat transfer

- What is an infrared flocking sheet?

- Application of thermal transfer technology in clothing

- The advantages and disadvantages of flocking fabrics

- What is rhinestone velvet made of?

- Laser marking: How to increase the marking rate of fiber las

Transfer Information Article

- What is rhinestone velvet made of?

- What is the washing water mark?

- Is the dry stage of electric heaters particularly important

- The advantages and disadvantages of flocking fabrics

- The main purpose of transfer flocking paper shows the overal

- Application of laser marking technology

- Laser marking: How to increase the marking rate of fiber las

- What is an infrared flocking sheet?

- What is flocking paper? What are the advantages and disadvan

- What is flocking printing?

- Application of thermal transfer technology in clothing

- How to do flocking

- What is flockde paper

- How to use heat transfer flocking heat transfer

- The advantages and disadvantages of flocking wallpaper Const